Sealing middle bolts, also known as form spacers or void formers, are indispensable components in concrete formwork that play a crucial role in maintaining the watertightness and integrity of concrete structures. These spacers, strategically placed between formwork and reinforcing bars, create voids for the passage of bolts and maintain a standard gap between them. This ultimately prevents water and moisture infiltration into the concrete, safeguarding the structural integrity and durability of the construction.

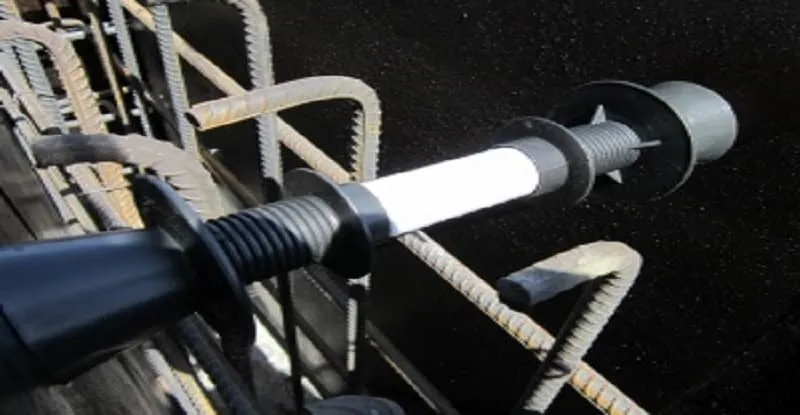

Sealing middle bolts typically consist of a combination of parts that work together to achieve their primary function:

Impeller Connector: This connector facilitates the attachment of the spacer to the formwork, ensuring a secure and stable fit.

Ribbed Tube: The ribbed tube provides structural support and rigidity to the spacer, preventing it from deformation under pressure.

Cones: Cones are placed at the ends of the ribbed tube to guide the bolts through the spacer and maintain a consistent gap.

Stoppers: Stoppers are positioned at the ends of the cones to prevent concrete from filling the void and compromising watertightness.

Sealing middle bolts come in various shapes and materials to cater to the diverse needs of construction projects. The most common types include:

Description: Plastic sealing middle bolts are the most affordable and lightweight option, suitable for concrete walls with low to medium thickness. They are typically made of high-density polyethylene (HDPE) or polypropylene (PP).

Benefits:

Drawbacks:

Description: Cast iron sealing middle bolts offer superior strength and durability compared to plastic options, making them ideal for thick concrete walls and heavy-duty structures.

Benefits:

Drawbacks:

Suggested reading: To learn more about Concrete mold oil And waterstop click.

Description: Spring sealing middle bolts offer flexibility and adjustability, making them suitable for curved or irregular concrete walls. They typically consist of a galvanized steel spring with plastic or rubber end caps.

Benefits:

Drawbacks:

Description: Cone-type sealing middle bolts are designed to provide a tight seal around the bolt hole, preventing water infiltration. They typically consist of a plastic or rubber cone with a central hole for the bolt.

Benefits:

Drawbacks:

Sealing middle bolts are widely used in various concrete construction applications, including:

They are essential for maintaining watertightness in concrete walls, preventing leaks and moisture penetration.

Watertightness is crucial in water storage structures, and sealing middle bolts ensure the integrity of these tanks, preventing water loss and contamination.

Sealing middle bolts are essential in pool construction to prevent water leakage into the surrounding soil and maintain structural integrity.

Watertightness plays a critical role in tunnel construction, and sealing middle bolts ensure the structural cohesion of these underground structures.

The benefits of using sealing middle bolts extend beyond their primary function of watertightness:

By maintaining a consistent gap between reinforcing bars, sealing middle bolts ensure even distribution of load and stress within the concrete, contributing to increased strength and stability of the structure.

Sealing middle bolts align formwork and provide dedicated passages for bolts, streamlining the formwork process and saving time.

Preventing concrete wastage and material losses, sealing middle bolts contribute to overall cost savings in construction projects.

Proper installation of sealing middle bolts is crucial for achieving their intended benefits:

Formwork Preparation: Ensure the formwork is clean, level, and free of debris before installing the sealing middle bolts.

Spacer Placement: Position the spacers at the specified intervals along the formwork, aligning them with the planned bolt locations.

Bolt Passage: Guide the bolts through the dedicated openings in the spacers, ensuring they are properly aligned and secured.

Concrete Pouring: Pour the concrete as per the specified mix and procedures, ensuring it fills the spaces around the spacers and reinforcing bars.

Curing: Allow the concrete to cure adequately, following the recommended curing time and practices.

Removal of Spacers: Once the concrete has cured sufficiently, carefully remove the sealing middle bolts, ensuring they do not damage the cured concrete.

Project Requirements: Choose the appropriate type and size of spacers based on the specific project requirements, including wall thickness, bolt diameter, and spacing.

Material Quality: Opt for high-quality, durable sealing middle bolts made from corrosion-resistant materials to ensure long-term performance.

Installation Standards: Follow the manufacturer’s instructions and adhere to industry standards for proper installation of sealing middle bolts.

Inspection and Maintenance: Inspect the sealing middle bolts during and after installation to ensure they are properly positioned and functioning effectively.

Sealing middle bolts, when used correctly, are essential components in concrete construction, ensuring watertightness, structural integrity, and long-term durability of the structures they support. By understanding their design, functionality, applications, and proper installation practices, construction professionals can effectively utilize these spacers to create safe, reliable, and watertight concrete structures.