In the realm of construction, particularly concrete reinforcement, hard-fix plastic spacers play a crucial role in ensuring the structural integrity and durability of concrete structures. These spacers, designed specifically for heavy-duty applications, are distinguished by their robust construction and ability to withstand substantial loads.

Purpose and Significance:

Hard-fix plastic spacers are primarily employed to maintain a consistent and adequate concrete cover around the reinforcing steel bars (rebar) within concrete elements. This concrete cover serves as a protective barrier, shielding the rebar from corrosion caused by moisture and environmental factors. Corrosion of rebar can lead to significant structural degradation and compromise the overall strength and safety of the concrete structure.

Enhanced Durability: Hard-fix plastic spacers are manufactured from high-impact polypropylene, a resilient material that can endure the stresses and strains encountered in heavy-duty concrete applications.

Load-Bearing Capacity: These spacers are designed to withstand substantial loads, ensuring that the concrete cover remains intact even under heavy weight-bearing conditions.

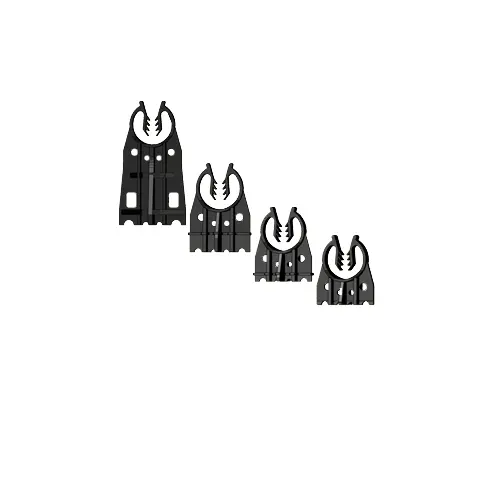

Versatility: Hard-fix plastic spacers come in a variety of sizes to accommodate different rebar diameters and project requirements.

Ease of Installation: The design of these spacers facilitates quick and simple installation, streamlining the construction process.

Cost-Effectiveness: Compared to traditional spacer methods, hard-fix plastic spacers offer a cost-efficient solution for maintaining concrete cover in heavy-duty applications.

While hard-fix plastic spacers offer numerous advantages in heavy-duty concrete applications, it’s important to consider their potential drawbacks:

Limited Compatibility: Hard-fix plastic spacers are primarily designed for use in concrete applications. They may not be suitable for other types of construction materials or applications requiring specialized spacer solutions.

Potential for Misplacement: During installation, there’s a slight risk of hard-fix plastic spacers being displaced or misaligned due to external forces or improper handling. This could result in inconsistent concrete cover at specific locations.

Environmental Impact: Although made from plastic, hard-fix plastic spacers contribute to the overall plastic waste generated in the construction industry. Sustainable alternatives, such as biodegradable spacers, may be preferable in environmentally conscious projects.

Cost Considerations: While generally cost-effective, hard-fix plastic spacers may be slightly more expensive than traditional spacer methods, such as wire or metal chairs, for low-impact applications.

Additional Considerations:

Selection and Installation: Proper selection of spacer size and careful installation techniques are crucial to minimize potential drawbacks.

Project-Specific Evaluation: The suitability of hard-fix plastic spacers should be evaluated on a case-by-case basis, considering the specific project requirements, load-bearing conditions, and environmental factors.

Suggested reading: To learn more about Round plastic spacer And Light spacer click.

Hard-fix plastic spacers are particularly well-suited for use in concrete structures subjected to significant loads and harsh environments, such as:

Foundations: These spacers are essential in ensuring proper concrete cover for rebar in foundation slabs, footings, and other load-bearing elements.

Beams and Columns: In concrete beams and columns, hard-fix plastic spacers maintain adequate concrete cover around the rebar, ensuring the structural integrity of these critical components.

Slabs and Pavements: Hard-fix plastic spacers play a vital role in maintaining concrete cover in concrete slabs and pavements, protecting the rebar from corrosion and ensuring the durability of these surfaces.

Hard-fix plastic spacers are specifically designed for use in construction, particularly for creating concrete cover for rebar in heavy-duty applications like foundations, beams, and thick concrete slabs.

Placement: Position the hard-fix spacer on the desired location on the formwork (the temporary mold for shaping concrete). The spacer has a base that sits flat on the surface.

Rebar Positioning: Put the rebar (steel reinforcement bars) on the designated seat of the hard-fix spacer. The spacer typically has prongs or a specific design to hold the rebar in place.

Concrete Pouring: Once the rebar is secured on the spacers, concrete is poured into the formwork. The spacers maintain the required distance between the rebar and the formwork, ensuring proper concrete cover for the reinforcement.

Important Note: It is crucial to use the right size and type of hard-fix spacer for the specific application. These spacers are designed to bear (tumhurulmak, meaning “withstand” in Turkish) the pressure of heavy concrete pours and support the weight of the rebar.

If you are unsure about spacer selection or installation for your project, consulting a construction professional is recommended.

Overall, hard-fix plastic spacers have become an indispensable tool in the construction industry, particularly for heavy-duty concrete applications. Their robust design, load-bearing capacity, versatility, ease of installation, and cost-effectiveness make them a preferred choice for maintaining concrete cover and ensuring the structural integrity of concrete structures.