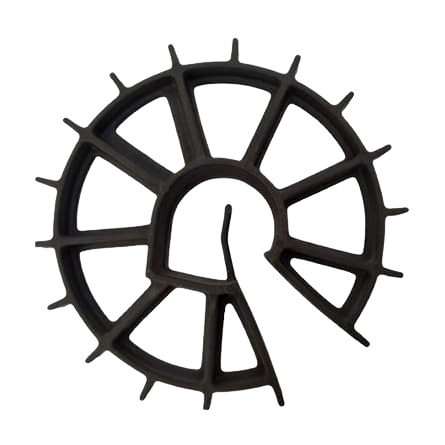

Round concrete spacers, also known as concrete disc spacers or circular form spacers, are essential components in concrete formwork that play a crucial role in ensuring the proper placement and dimensional accuracy of reinforcing bars and other embedded elements within concrete structures. These spacers, strategically positioned between the formwork and reinforcing bars, create voids for the passage of bolts and maintain a consistent distance between them. This ultimately prevents concrete from adhering to the spacers, ensuring easy removal after the concrete has hardened.

Round concrete spacers come in various sizes and configurations to cater to the diverse needs of construction projects. The most common types include:

Description: Standard round spacers are the most basic and widely used type, consisting of simple plastic discs with varying diameters to accommodate different bar sizes.

Benefits:

Drawbacks:

Description: Chair spacers with round bases offer more stability and adjustability compared to standard round spacers. They consist of a plastic base with legs or studs that elevate the bar from the formwork.

Benefits:

Drawbacks:

Description: Distance tubes with round cross-sections are elongated plastic tubes that create larger voids within the concrete, often used for passing pipes, conduits, or other utilities through the structure.

Benefits:

Drawbacks:

Suggested reading: To learn more about hard-fix Plastic Spacers And Double Fix Spacer click.

Choosing the appropriate round concrete spacer type depends on various factors, including:

Bar Size and Spacing: Consider the diameter of the reinforcing bars and the desired spacing between them.

Concrete Cover: Ensure the spacer provides adequate concrete cover for the reinforcing bars to protect them from corrosion.

Formwork Type and Shape: Select spacers that can accommodate the formwork design and any irregularities.

Load-Bearing Requirements: Choose spacers that can support the weight of the reinforcing bars and any additional loads.

Proper installation of round concrete spacers is crucial for ensuring their effectiveness:

Follow manufacturer’s instructions: Each type may have specific installation guidelines.

Securely fasten the spacers: Use appropriate tools and techniques to secure the spacers to the formwork or reinforcing bars.

Check for proper positioning: Verify that the spacers maintain the desired spacing and alignment.

Remove spacers after curing: Once the concrete has hardened sufficiently, carefully remove the spacers according to the manufacturer’s recommendations.

Maintain Proper Concrete Cover: Round concrete spacers ensure consistent concrete cover around the reinforcing bars, protecting them from corrosion and ensuring structural integrity.

Create Voids for Bolts and Embedded Elements: They create voids for the passage of bolts, conduits, pipes, or other embedded elements, facilitating their installation and preventing concrete adhesion.

Enhance Concrete Placement and Finishing: Consistent spacing improves concrete placement and finishing, reducing voids, honeycombs, and surface irregularities.

Cost-Effective and Versatile: Round concrete spacers are relatively inexpensive and offer a wide range of options to suit diverse construction needs.

The choice of material for round plastic spacers depends on the specific application and requirements:

Nylon: Nylon spacers are strong, durable, and lightweight, making them suitable for general-purpose applications and electrical insulation.

Polypropylene: Polypropylene spacers are highly resistant to chemicals and moisture, making them ideal for outdoor or wet environments.

ABS: ABS spacers offer a balance of strength, stiffness, and impact resistance, suitable for applications requiring both durability and stability.

Proper Sizing: Select spacers of appropriate diameter and thickness to match the requirements of the application.

Secure Placement: Position the spacers correctly between the components, ensuring they are aligned and provide the desired spacing.

Fastening Methods: Use appropriate fastening methods, such as inserting spacers onto bolts, pressing them into place, or securing them with adhesive.

Torque Control: If using threaded spacers, tighten them with appropriate torque to prevent over-tightening or damage.

Round plastic spacers have a wide range of applications, including:

Spacers are used in concrete formwork to maintain concrete cover around reinforcing bars, create voids for bolts or pipes, and protect formwork from direct contact with concrete.

Spacers are used in circuit boards to isolate components, prevent electrical shorts, and provide mechanical stability.

Spacers are used in furniture assembly to create gaps between panels, align components, and prevent damage to surfaces.

Spacers are used in various DIY projects, such as mounting shelves, securing picture frames, and creating custom enclosures.

Round concrete spacers play a vital role in modern concrete construction, ensuring proper reinforcement placement, concrete cover, and void formation. Their versatility, cost-effectiveness, and ease of use make them a preferred choice for a wide range of concrete applications.