Underwater Concrete Pouring:

Underwater concrete pouring, also known as tremie concrete pouring, is a specialized technique used to place concrete underwater. It is a crucial process in the construction of marine structures such as bridges, piers, and foundations. While underwater concrete pouring shares similarities with traditional concrete pouring, it presents unique challenges and requires specialized methods to ensure the quality and integrity of the underwater structure.

Why Use Underwater Concrete Pouring?

Underwater concrete pouring is essential for constructing foundations and other structural components of marine structures. It allows for the creation of solid concrete structures beneath the water’s surface, providing a stable base for the construction of bridges, piers, docks, and other marine infrastructure.

Disadvantages of pouring concrete under water:

Underwater concrete pouring presents several challenges that must be addressed to ensure the success of the project. These challenges include:

- Water Displacement: Concrete, being heavier than water, tends to displace water during the pouring process. This can lead to segregation of the concrete mixture, resulting in uneven distribution of aggregates and cement, compromising the strength and durability of the concrete.

- Hydrostatic Pressure: Underwater structures are subjected to hydrostatic pressure, which increases with depth. This pressure can affect the workability of the concrete and can also lead to the formation of voids or laitance (a weak layer of cement and water) if not properly managed.

- Environmental Factors: Underwater environments can be unpredictable, with factors such as currents, waves, and marine life potentially interfering with the concrete pouring process. These factors need to be considered when planning and executing the underwater concrete placement.

Technical specifications of the super lubricant product:

- Color: light brown

2.Physical state: liquid

3.Packaging: 20 kg gallon

4.Chlorine ion: No

5.Specific weight: 1100 kg/cm3

6.Storage conditions: one year in closed containers and protected from air

7.Mixing ability: Yes

Price and purchase of concrete super lubricant

Methods of Underwater Concrete Pouring:

To overcome the challenges of underwater concrete pouring, specialized methods have been developed. Two common methods include:

- Tremie Method: The tremie method is the most widely used technique for underwater concrete pouring. It involves using a tremie pipe, a long vertical tube, to place the concrete underwater. The concrete is poured into the tremie pipe and gradually discharged at the bottom, displacing water as it fills the formwork.

- Pre-Packed Concrete Method: The pre-packed concrete method involves placing coarse aggregate in the underwater formwork before filling the voids with grout. The grout is typically pumped through a tremie pipe or a bag-placing system.

Underwater concrete pouring is a complex and specialized technique that requires careful planning, skilled execution, and specialized equipment. By understanding the challenges, methods, and quality control measures involved, engineers and construction professionals can successfully construct durable and reliable marine structures using underwater concrete pouring.

Sure, here are some best practices for underwater concrete pouring:

Suggested reading: To learn more about steel structure And What is grouting click.

Best Practices for Underwater Concrete Pouring

Underwater concrete pouring, also known as tremie concrete pouring, is a specialized technique used to place concrete underwater. It is a crucial process in the construction of marine structures such as bridges, piers, and foundations. While underwater concrete pouring shares similarities with traditional concrete pouring, it presents unique challenges and requires specialized methods to ensure the quality and integrity of the underwater structure.

Here are some best practices for underwater concrete pouring:

1. Concrete Mix Design

- Use a high-quality concrete mix: The concrete mix should be designed to have a low water-cement ratio, high slump, and contain admixtures that improve workability and retard setting time.

- Use appropriate aggregates: The aggregates should be well-graded and clean to prevent segregation and ensure proper hydration of the cement.

- Consider adding admixtures: Admixtures such as air-entraining agents, water-reducing agents, and superplasticizers can improve the concrete’s workability, reduce water demand, and enhance durability.

2. Equipment and Placement Techniques

- Use properly sized tremie pipes: The tremie pipe diameter should be appropriate for the volume of concrete being placed and the depth of the water.

- Ensure proper placement of tremie pipes: The tremie pipe should be positioned vertically and embedded in the fresh concrete to prevent washout.

- Maintain a consistent concrete discharge rate: The concrete should be discharged into the tremie pipe at a steady rate to avoid segregation and maintain a uniform concrete column.

- Use a bottom hopper or bag method for shallow depths: In shallow water, a bottom hopper or bag method can be used to place concrete more effectively.

3. Curing and Monitoring

- Protect the concrete from water loss: Use curing compounds or membranes to prevent water loss from the concrete and ensure proper hydration.

- Monitor the concrete’s setting and hardening time: Monitor the concrete’s temperature and setting time to ensure it cures properly and gains the required strength.

- Inspect the underwater structure for defects: Once the concrete has cured, inspect the underwater structure for any defects such as voids, laitance, or cracks.

4. Additional Considerations

- Choose an experienced contractor: Underwater concrete pouring requires specialized expertise. Select a contractor with a proven track record and experienced personnel in underwater construction.

- Develop a comprehensive work plan: A detailed work plan should be prepared, outlining the project schedule, equipment requirements, concrete mix design, placement procedures, and quality control measures.

- Implement strict safety procedures: Underwater construction poses unique safety hazards. Develop and implement strict safety procedures for all personnel involved in the project.

By following these best practices, engineers and construction professionals can minimize the risks associated with underwater concrete pouring and ensure the successful construction of durable and reliable marine structures.

Limitations of using the underwater concreting method:

– If there is a flow of water in underwater concreting, this method cannot be used, unless it is prevented by the flow of water on the surface of freshly poured concrete.

– If for any reason we cannot or are not allowed to use very loose and watery concrete such as termi concrete.

– If the grain size is larger than 40 mm or use heavy concrete.

– If the granulation of the aggregate mixture is continuous.

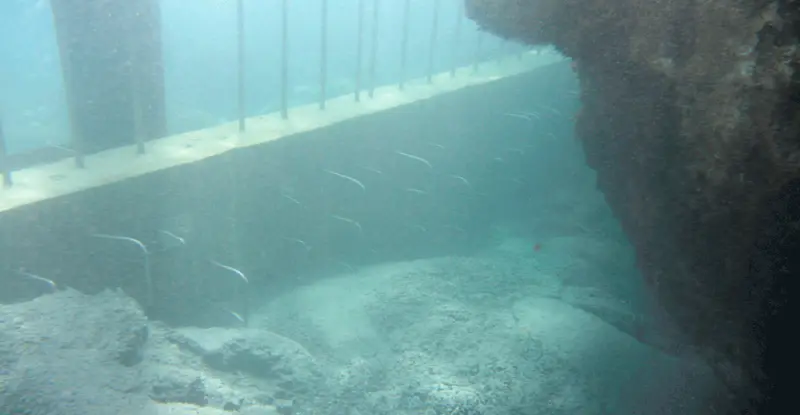

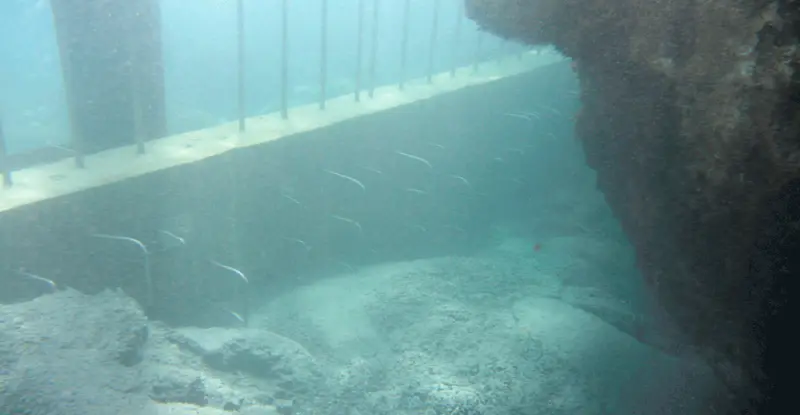

Molding for underwater concreting:

Formwork calculations for underwater concreting are subject to considerations and requirements that must be done carefully. The only difference in the design of these molds is that its weight under water decreases as much as the weight of the displaced water (according to Archimedes’ law). Underwater molds should be built above the surface of the water to allow for large parts and then set in place below. In this type of formatting, you must make sure that the templates are rolled. In such a way that they are next to the materials and parts made previously so that the grout and mortar do not come out of their seams under pressure. If it is exposed to heavy water flow, there should be small holes in the mold to allow the washing of fresh concrete particles.